Service is our Business. Heat Exchangers are our Product.

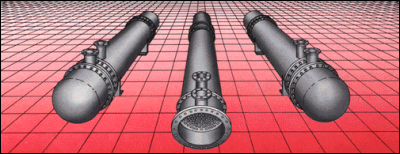

Shell & Tube Heat Exchangers

HOFFMAN PROCESS, INC. designs and provides shell and tube exchangers to the ASME Code and TEMA standards in metals of carbon steel through Hastelloy and titanium. We offer the total range of TEMA designs including floating tubesheet, 2-pass shell, shell cross flow, and double tubesheet designs. Thermal and Mechanical Design, developed with In-House and licensed Software, including B-JAC. Drawings are prepared with In - House Auto-CAD system.

Roller expanded tube-to-tubesheet joints with TEMA grooves are standard. We also offer welded tube-to-tubesheet designs including fillet, fusion and trepanned construction. We design exchangers through 3000 psig and for temperatures compatible with selected materials. Also available is lethal service and 100% x-ray construction.

Standard Designs

Standard designs are with 3/4" O.D. by 8' long tubes on 15/16" triangular pitch. Designs are 150 PSIG at 300° F both sides, per ASME Section VIII, Div. 1 and TEMA Class "C", and with the "U" stamp. Horizontal or vertical mounting available. See Bulletin HP-88 for our standard design of exchangers with 5/8: O.D. tubes.

Hoffman Process, Inc.'s Line of Standard Pipe-Size Shell and Tube Heat Exchangers offers the following features:

- Computerized Thermal and Mechanical Design

- Computerized Drawing

- ASME Code and TEMA Standards

- 3/4" O.D. Tubes as Standard with 5/8", 1" and Larger Diameter Available.

- Materials: Carbon Steel through Hastelloy

Special Designs, Materials and Higher Pressures Available Upon Request

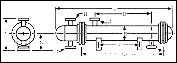

BEM

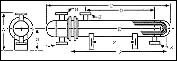

BEU

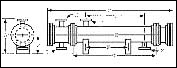

AES

Hoffman Process, Inc. offers a complete line of heat exchangers including air cooled, transition, spiral, plate, plate fin, double pipe, and tank heaters. Also custom designed stripping and distillation systems, and shop-built modular systems.